Expandable cartridge heaters solve two major issues of conventional high-density heaters: low durability and inadequate removal fitting. They improve temperature precision with hundreds of fittings and outlets for all types of processes.

With expandable cartridge heaters, we combine for the first time the best of the conventional cartridge heater with a cartridge and an adaptable, quick and simple removal fitting.

Cold HeatSelf-expanding cartridge heater

Longer lifeThe expandable cartridge is a high-performance compressed cartridge made with top-quality materials, featuring a unique forked design tensioned at a specific point, allowing it to expand and retract on its own.

Purity of materials

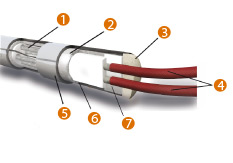

Expan resistors are manufactured through an internal compaction process of all components to increase lifespan. The Nickel/Chrome 80/20 conductor wire is inserted into the cavities of a ceramic core that centers it, obtaining the ideal spacing for better insulation. All is coated with high purity magnesium oxide and controlled granularity to ensure complete filling of the Expan cartridge. Then a compaction process and surface grinding calibrate it to the desired size. Finally, it undergoes rigorous quality control to guarantee the best cartridge performance. We do not use these 4 materials: Tantalum, Tin, Gold, and Tungsten.

Facilities and the unique construction system guarantee maximum internal purity, ensuring a longer lifespan.

Hundreds of terminations

The perfect companion: thermocouples

Cartridges can be built with an integrated probe at any point on the cartridge upon customer request. The advantages of including probes are numerous, for example: significantly extending cartridge life, localized temperature accuracy, energy savings, and adaptability where conventional probes cannot fit due to space constraints.

Technical Data

| Voltage (V) | 120 - 130 - 240 - 380 - 400 |

| Power tolerance (w)* | + 5 % - 10 % |

| Power | Depends on dimensions |

| Length tolerance | ± 3% max 20mm |

| Standard diameter tolerance | -0.10 to -0.15 mm |

| Leakage current* | <=0.5mA at 253 V |

| Aislamiento* | >=5 MΩ at 500 V |

| High voltage resistance* | 1500V to > 24V operating voltage |

| 500V to > 24V operating voltage | |

| Tube material | Stainless Steel |

| Wire | NiCr 8020 |

| Melting temperature | 750º C |

*tested at room temperature

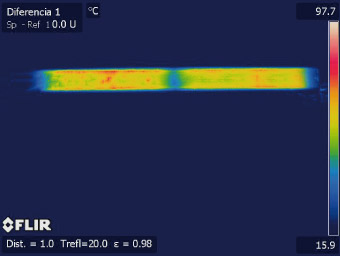

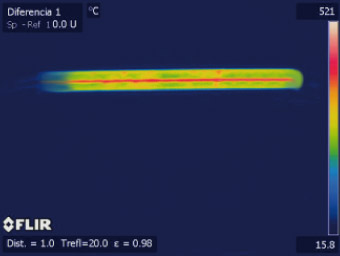

Uniform heat

Expan heaters are made with a single spring-shaped heating wire, which contains more wire than any other cartridge heater model. This results in more uniform heat distribution around the perimeter with no cold spots or temperature fluctuations.

The resistance that fits the hole

Expansion throughout the entire cartridge perimeter makes the Expan resistance the best solution for larger diameter holes caused by wear, expansion, or made with loose tolerances.

The fitting tolerance of the resistance is defined as the distance between the cartridge surface and the inner hole wall, which must be uniform along its entire linear perimeter.

Extraction is faster and easier, even at long lengths.

Expan resistors, due to their unique construction system, allow easy removal when the cartridge is cold, saving significant time and effort, minimizing machine downtime and human resources. No adjustment paste is needed and no drilling, destruction, or costly operations are required to remove the cartridge. You can reuse Expan resistors in other molds that need heating.

Precision in expansion

Maxiwatt expandable cartridges are designed to have the widest tolerance range of all quality heaters on the international market.

All intermediate sizes in diameter and length, voltages, watt distribution, cold spots, special finishes, terminations, etc., can be manufactured.

| Ø | Drilling | Ø real | Zona fría | Minimum length |

Maximum length |

Maximum amps according to length |

|

| 3/8'' | 9,52 ±0,1 | 9,3 | 20 | 100 | 1000 | 15 | 15 |

| 10 | 10 ±0,1 | 9,8 | 20 | 100 | 1000 | 15 | 15 |

| 12 | 12 ±0,1 | 11,8 | 20 | 100 | 1500 | 25 | 25 |

| 12.5 | 12.5 ±0,1 | 12,3 | 20 | 100 | 1500 | 30 | 25 |

| 1/2'' | 12.7 ±0,1 | 12,5 | 20 | 100 | 1500 | 30 | 25 |

| 15 | 15 ±0,1 | 14,8 | 30 | 100 | 1500 | 40 | 25 |

| 5/8'' | 15,88 ±0,1 | 15,68 | 30 | 100 | 1500 | 40 | 25 |

| 16 | 16 ±0,1 | 15,8 | 30 | 100 | 1500 | 40 | 25 |

| 3/4'' | 19,05 ±0,1 | 18,85 | 30 | 100 | 1500 | 40 | 25 |

| 20 | 20 ±0,1 | 19,8 | 30 | 100 | 1500 | 40 | 25 |

| 25 | 25 ±0,1 | 24,6 | 30 | 100 | 1500 | 40 | 30 |

| 1'' | 25,4 ±0,1 | 25 | 30 | 100 | 1500 | 40 | 30 |

Longer useful life: the difference

The Expan resistance has more heating wire (Nickel/Chrome 80/20) than bipartite resistors or compressed cartridges with the same compression. The principle is key; the more heating wire, the larger the diameter must be for the same watts. A larger diameter reduces fatigue and wear of the heating wire, resulting in longer life.

Section of an Expan resistance with more heating wire per resistance.

Patent pending.